We Provide Single -Single machine of Corrugation Plant as well as whole plant as per cutomer’s requirement. Providing you the best range of pneumatic controlled corrugation machine & Plant ,double profile paper corrugation machine, fingerless corrugation machine, oblique type paper corrugation machine, 3/5 ply automatic corrugated board plant and 5 ply automatic corrugation board making plant with effective & timely delivery.

Corrugation Plant consist of following Machines-

1) Corrugation Machine

We are counted amongst the emerging manufacturers and exporters of all types of paper corrugation machine. The machine is designed with huge motorized reel stand that has a capacity of lifting 2-ton reel at a time. Owing to the flute rollers that are mounted on bearings, it provides smooth functionality and reliable performance. This machine is widely used for converting paper into 2 ply corrugated roll.

- Construction and operation : Enabled with rollers are bearing mounted

- Provided with one pre-heaters apart from the three regular heaters to de-moisturize the liner

- Equipped with twin shaft motorized self loading reel stand & bull

- Construction and Operation & bull : The flute rollers are mounted on bearings for smooth running & longer life

- The flute rollers are made of special alloy steel & bull

- The main bearings are lubricated with high temperature grease

- Enabled with gum rollers that are hard chromed for better performance & life

- Two pre-heaters are provided to de-moisturize the paper

- The variable speed motor is recommended for better quality and economy in wastage at an additional cost

- Capacity to lift up to 1 ton reel

- Variable drive motor is standard with this model

- Provided with 'Jumbo' type motorized Hydraulic reel stand can be at an additional cost Single facer finger type / fingerless

Features:

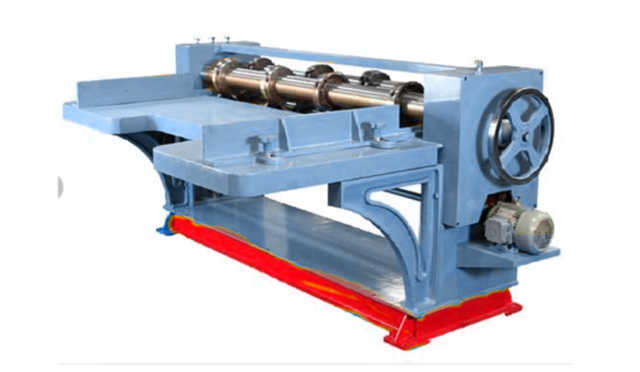

2) Reel to Sheet Cutter

The perfectly built & designed to increase production and fine cutting of corrugated board without damaging the flutes of the board as well as plain paper. As a perfect alternative to Hand Operated Board Cutting Machine. It is possible to use the machine as an independent unit or it can also be attached with the corrugating Machine. If required P.I.V Gear Box is provided to ensure accurate cutting of the sheet as per required length and easy to adjust and operate. Delivery Conveyor Stand is provided to carry the Sheets. This Machine is designed for high production and straight cutting of sheets or two ply corrugated board without damaging flutes & liner paper. Mostly, this machine is used as an independent unit for direct and accurate sheet cutting.

- Machine is having special feature of oil bath gear system with oil lubricating pump

- Machine is fitted with heavy duty excel makes P.I.V. Gear Box

- Imported chain to adjust the length of the sheet to be cut with Gear Ratio 1:5

- Machine is driven by A.C. frequency drive with provision for synchronization of speed between Sheet Cutter with Corrugating Machine

- With A.C. Motor & Starter

- Feeding section with concealed gears

- Cutting section with Blade workable at four edges

- Delivery conveyor with endless Belts

- Electronic sheet counter

- Paper cutting capacity is 200 feet per minute

Features:

The machine is exclusively designed and manufactured for the pasting of corrugated sheets of different ply. Simple in design, strong in construction, easy to operate and is assured of faultless working during continuous operation. The rolls of the machine are smoothly finished to ensure even impression on the boards after lamination. The machine is used for applying glue on the tip of the corrugated surface and pasting corrugated sheets of different ply and thickness. This machine is known for its robust construction and ability continuously running at even high speeds.

- Resistivity to adverse conditions

- Easy operation

- Dimensional accuracy

- High tensile strength

- Longevity

Features:

This machine is another contribution to the packaging industry for trimming and creasing the corrugated board simultaneously. The machine is easy to operate & sturdy in construction. Easy setting is provided for adjusting, creasing & cutting heads on this machine. Measure is provided for accurate cutting & creasing of sheets. The machine has sturdy construction and contains graded alloy steel knives for smooth cutting. The speed is 300 ft. per minute and the minimum distance between two dies is 3 inches.

- The machine is sturdy in design

- It contains graded alloy steel knives for long life sharpness and smooth cutting

- The creasing dies are common in 3 and 5 ply, 7 and 9 ply and above

- The shafts of machine are mounted on heavy duty bearings for smooth running noise free with graded casting gears and nylon gears

- Minimum distance between two dies is 3 inches

- All moving parts are protected by safety guards

Features:

The Eccentric Slotter Machine is provided with four slotting cutters. The dies are mounted on an eccentric shaft which causes them to move in an arc so that the board is slotted in a shearing manner. The dies can be moved and slot depth adjusted easily. Simple in design, strong in construction, easy to operate and is assured of faultless working during continuous operation. This machine is used to punch out slots and stitching edge in the corrugated sheets. This manually operated machine is capable of slotting number of sheets at a time.

- The machine has three slotting & one corner cutting head and gauges are provided for accurate feeding.

- Three slots and one corner cutting is done simultaneously on the machine.

- It is available in 2, 3 and 5 HP capacities with 2200, 2800, 3000, 3200 and 3400 of weights.

- The distance between slotting and corner cutting heads are adjustable with gear rack mechanism provided with the machine.

- Two side gauges are provided for accurate feeding.

- The upper dies move in an arc so that the board is slotted in a shearing manner.

- Minimum distance between two dies is 7" corner width is 3.5".

Features:

Flexo printing machine used for printing on plain Kraft paper Print through Photo Polymer Stereos Registration for Accurate Printing Suitable for Short Print Run Hand Brake to Release the Eccentric Pressure Controlled Transfer of Ink. Available in option of Single Color unit, Double Color Unit and Tripple colour unit.

We provide an exclusively stitching machine which is suitable for cardboard, corrugated board, using round or flat wire. This Machine is meant to stitch the corrugated boxes. The machine is driven by coil spring clutch. The pulley of the machine runs at the speed of 350 rpm so we can stitch maximum 350 pins per minutes. The machine is fitted with thickness setter to adjust the gap depending on the board thickness. The parts are standardized and are inter changeable and made of alloy steel. This machine is exclusively designed for accuracy and quality stitching. This machine is available in Straight and Angular model.

- The pulley of the machine runs at the speed of 350 rpm so we can stitch maximum 350 pins per minutes

- This Machine is meant to stitch the corrugated boxes

- The machine is driven by coil spring clutch

- The machine is fitted with thickness setter to adjust the gap depending on the board thickness

- The parts are standardized and are inter changeable and made of alloy steel

- This machine is exclusively designed for accuracy and quality stitching

- This machine is available in Straight / Angular / Bottom models

Features:

Suitable for cutting paper, corrugated liners & boards. The machine is fitted with front and back guides for measurement and the blade is perfectly balanced for smooth cutting. The Board Cutter Machine is hand-operated machine used for cutting the paper or corrugated board. The machine is heavy duty made from fabricated Iron Frame and heavy duty Cutting knife for easy operation and durability.

We bring forth our top class Heavy Duty Platen Punching Machine that is equipped with Electro-Magnetic Clutch and Brake for simple operations. Manufactured using the best quality raw materials, En Graded Components, this Platen Die Punching Machine is capable and designed for Die-Cutting, Creasing, Punching and Embossing Job on various Products such as Paper, Card Board, Corrugated Board, Fiber Board, Vinyl, Foam, Rubber, Leather, Masonite, Cork Sheets, Glued Boxes, Advertising Cut out, Jigsaw Puzzles, Labels and much more.

Our Machine can also provide half cuts for stickers. The perfect sticker cutting is ideal thus, the die blade should cut through the face paper & the adhesive should come to stop just before the release of paper. We make it 100% percent possible by introducing these features in our Platen Die Punching Machine. In addition to this, the Platen Die Punching Machine that we offer complies with the set industrial standards. Our valued clients can avail the Platen Die Punching Machine manufactured by us in various sizes as per their needs.

Enquiry Now